Warehouse Solutions

- Overview

- Selective Pallet Racking

- Drive-in Racking

- Multitier and VNA Racking

- Mobile Racking and Satellite Racking

- Gravity Flow Racking

- Push Back Racking

- Cantilever Racking

- Double Deep Racking

- Accessories

- Workbenches

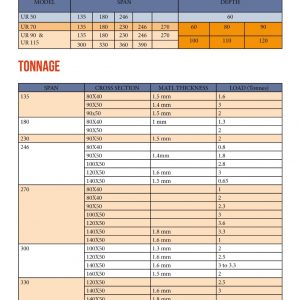

Frames

• Cold roll formed uprights and the bigger Omega cross sectional rofile results in higher upright stiffness and rigidity.

• Punched with lug holes at 76mm pitch for easy clearance calculation and load bearing capacity, and cold roll-formed into a C-section with return flanges for stronger load capacity.

• 90mm x 76mm Continuous Uprights Without Splice, bolted with horizontal and diagonal braces using high tensile grade 8.8 bolts and nuts.

• All uprights are designed with a guaranteed safety factor of 1:2

• Frame Load Capacity-10 to 20 Tons

• SIZES OF UPRIGHTS: UR50, UR70, UR90 , UR115

Bracing

Steel braces of C-section profiles of 8×30.5x32x30.5x8mm x 1.5mm thick are bolted to the uprights in a constant zigzag pattern at every 60-centimetre using M10 x 65 high tensile Grade 8.8 bolts and nuts.

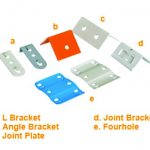

Heavy Duty base plates (shim plates)

125mm x 110mm x 6mm thick complete with 2 x M14 holes and Floor Anchors Mechanical Expansion Anchors M10 x 114.

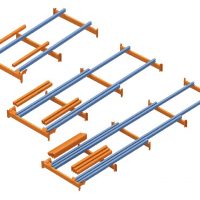

Beams

• Beams are welded to 3 lug end connectors for ease & quick hooking/ installation.

• The end connectors are welded using a robotic continuous welding machine, which guarantees consistent welding properties and according to international standards.

• Special safety locks complete the beam design to prevent accidental beam removal. These special safety locks does not deform easily when pulled out for repositioning of beams.

• All beams are designed with a guaranteed Safety Factor of 1:1.65 and limited to a maximum Deflection Ratio of Span/200.

• SIZES OF BEAMS : 80X40MM , 90X50MM, 100X50MM, 120X50MM, 140X50MM, 160X50MM

FINISH

Both frames and beams are epoxy powder-coated. All racking and shelving components are subject to anti-rust pre-phosphate treatment before epoxy powder is oven baked and coated hard on to the steel surface.

System code in practice

Our system follows the SEMA Code of practice to ensure proper load capacity & safety aspect.

Steel specifications

The system design includes the use of high tensile steel for its main racking components – uprights, braces and beams. The steel used in the manufacture of these components is no less than SS400 grade for the beams and SS490 for the uprights

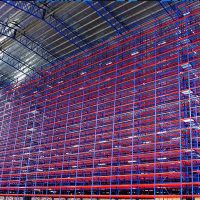

Selective Pallet Racking is the most common and cost effective storage system providing direct access to all pallets. It provides high capacity storage, is easily installed and adjusted, and has low equipment and capital costs.

Five Continents Group is a pioneer in this field & has adjustable pallet racking that can be constructed in single or back to back rows, the aisle widths being determined by the forklift trucks and handling equipment.

Standard Sizes available :

- Height : 1500 mm upto 12000 mm

- Width : 600/800/900/100/1100/1200 mm

- Length : 1350/1800/2460/2700/3000/3300/

3600/3900 mm L - Pallets can be located, accessed and moved individually.

- Rapid handling of almost all types of palletized goods.

- Infinitely adjustable and offering a wide range of options and components to accommodate specialized needs.

- Maximizes the space in warehouse while retaining optimum product accessibility.

- Can be used with standard forklift trucks and handling

- Bottom level of pallets can be stored on the floor, lowering structure costs.

- 100% Selectivity

Colour of Upright – RAL 5017, Blue

Colour of Beam – RAL 2011,orange

Carrying capacity – 500 to 3500 kgs. UDL per pair of beam level

Brand : EONMETALL , MALAYSIA

Shelf Decking : Galvanized drop over panel ( 275 GSM ZInc coated )/ 18mm Marine plywood decking

Floor : Galvanized Gratings

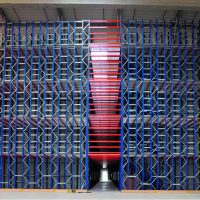

This type of racking is usually advised for those facilities operating a large volume of identical goods. Created to offer maximum storage capacity by using up only minimum space, this drive-in drive-through racking system consists of blocks undivided by aisles. This system is designed to efficiently suit the storage of homogeneous products in large quantity. Picking and storage is facilitated by forklift trucks driving right into the racks.

Drive-In Racking : Picking and replenishment are carried out fromone side.FILO Syestem

Drive – Through : Both Sides are used to access

Features:

- Enables perfect pallet turnover

- Maximum capacity as storage system is compact.

- Excellent Time and space saving in pallet handling.

- Excellent stock control.

Multi-tier racking

Multi-tier racking platforms maximizes all available headroom and is ideal for storing a wide variety of packaged goods for hand picking. It is the ideal solution for the utilizing of warehouse’s height and space. A Multi-tier racking floor offers a very cost-effective way of transforming unused headroom space into dynamic office, manufacturing or storage space, which allows a business to expand considerably within its existing premises. Multi-tier racking is created using adjustable pallet racking. Additional storage floors can be incorporated into the rack with walkways to allow pedestrian access for order picking. This maximizes all available headroom and is ideal for storing a wide variety of packaged goods for hand picking.

- Economical use of cubic space

- Can accommodate a range of storage requirement

- Ideal for archive storage

- Manual order picking applications

- Can accommodate sophisticated automated picking system

VNA – Very Narrow Aisle Storage System

Carefully-designed with no compromise on durability and safety, Eonmetall’s Very Narrow Aisle (VNA) racking systems feature aisles that are marginally yet sufficiently wider than the loads, making full use of roof height to create ultimate storage capacity for space-concerned customers. The system maintains the essential 100%-accessibility and outstanding goods protection feature to ensure quick picking rate and flawless stock rotation. VNA forklift truck equipment that comes with either man-up or man-down cabins that are capable of reaching higher beam levels are used in this exceptionally competent system.

Cantilever Racking System is suitable for storing longer items like pipes and tubes. This system provides easy storage and retrievability to the products. They comprise of frame structure with vertical beam / upright and horizontal arms connected to the vertical element. The goods are stored on the arms and the load is shared by a series of arms.

Features :

- Arms are fully adjustable allowing maximum use of space.

- Cantilever racking system maximizes steel storage and accessibility

- Cantilever racking systems are versatile for high-density storage for long spanstock

- Available in single-sided and double sided configurations

- A wide range of sizes & capacities.

- Storage caters for long or irregular shapes.

- Heavy-duty steel, will support extremely heavy loads

- The double sided rack provides maximum storage capacity on a single central column, while the single sided rack is designed to fit flush against the wall.

- The length of the shelf and the distance between the profile can be adjusted depending on the load.

We provide two kinds of Cantilever systems:

Heavy Duty Frame Cantilever

The vertical element is made of the EONMETALL Heavy Duty Upright frame. Arms are made with MS Tube or I-beam Connected to the frame structure by Heavy Duty Clip. This Option is suitable for Lighter goods. The arms could be adjusted without any need for additional tools.

I-Beam Structural Cantilever

This option is conceived and designed as per the client requirement. These are usually advised for the storage of Heavy items. The Structure would be fabricated using combination of standard beams and tubes as per the design calculations. Though the levels can be adjusted using standard spanner, these are not so easily adjustable as the Heavy Duty Cantilevers.

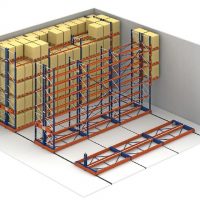

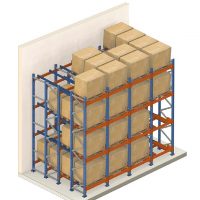

Designed to increase storage capacity, double-deep racking system is capable to store two pallets deep in a single-entry rack or four pallets deep in a double entry rack. This system is particularly beneficial when the throughput is low while fast movement of pallets is not critical. A special reaching truck with double-pantograph or extendable fork is used in this racking system.

Features :

- Increase in Storage Density

- Reduces Aisle to Rack Ratio

- First in Last out System (FILO)

- 50% Immediate Product Accessibility

- The Most Flexible System

- Cost Effective

- Suitable for wide variety storage

- Reasonable stock Rotation

- Require Special Reach Truck with dual pantograph / Slide Fork Attachments

Floor Utilization Approximation:

- Storage Area – 40%

- Operation Area – 60%

Advantages:

- Storage density increases as rack aisle ratio changes from Selective racking.

- 50% immediate accessibility with reasonable stock-rotation.

- Good use of all available locations, typically above 90%

- Best used when each SKU has several pallets.

LIGHT AND MEDIUM DUTY RACKING (NON-PALLETIZED)

This type of shelving provides cost efficient solutions for virtually any light duty storage requirement. The unique punched hole pattern allows multiple steel sections to be bolted together to form sturdy shelving and storage systems.

Standard sizes:

- Heights : 1800mm / 2000mm / 2400mm/ 3000mm

- Depth : 300/375/450/600 mm

- Length : 900mm L

- Colour :Grey

Advantages:

- A simple and economic system for a huge range of applications.

- Adaptable to all storage needs.

- Excellent versatility.

- Easy to assemble and dissemble.

- Weights of upto 150 kg UDL per level

Custom Frame Work:

We fabricate custom sized Slotted Angle Storage as per the client requirements. Usually the Decking would be Provided with GI Sheet or Plywood.

The Boltless Shelving System offered by Eonmetall is designed for light duty storage. The economical system consists of components which are simple to be assembled and installed without the hassles of using bolts and nuts or tools. There are also a comprehensive range of colour choices making it ideal for ambience. Adding to the excellent functionalities of the systems, the smooth lines and neat finishes provides aesthetic values to the storage system making the systems very much suitable for any types of storage system.

Advantages

- They are highly versatile and robust.

- Easily and quickly assembled.

- Excellent loading capacity and perfect stability.

- Totally adaptable to available space.

- They can be combined with other systems.

- Easily adjustable with the help of clips

- Weights of upto 200 kg UDL per level

Available Models:

Picolla racks :

- Colours : White /Black

- Size : 1800mm (h) x 900mm (L) x 350mm (w)

Yellow Bolt-free Rack:

- Size 1840mm(h) x 122cm (L) x 457mm (w)

These systems are available in an extensive range of sizes that come with either clad or open configurations. There are also a comprehensive range of colour choices making it ideal whether the customers needs a simple bay of shelving or a complex systems such as two-tier or high-rise order picking solutions.

The flexible bolt-free shelving systems provide an accommodating, modular hand loaded shelving system. Locked together, the bolt-free systems enable quick and easy construction and installation. Various sizes of open and closed configurations produce efficient storage for almost every possible item, ranging from small components to large cartons and boxes. On the other hand, accessories such as the shelf dividers and bin fronts allow handy segregation thus clear identification of various groups of stored items.

Adding to the excellent functionalities of the systems, the smooth lines and neat finishes provides aesthetic values to the storage system making the systems very much suitable for any types of storage system.

Advantages:

- Adaptable to all storage needs with optional partition available.

- Simple System Suitable for Variety of applications.

- Excellent versatility.

- Easy to assemble and dissemble.

- Weights of upto 150 kg UDL per level

- Versatile to be used as Multi-Tier systems

Long span is a strong, durable, versatile and economical shelving system that looks good and minimizes lost space from uprights making it ideal for a wide variety of applications from archives to automotive, factories, warehouses, retail, wholesale and commercial.

- High density storage of small items

- Storage of large, heavy and bulky items

- Storage of long, odd-shaped or awkward items

Long span has fully adjustable shelf heights, long spans. It’s suitable for everything from small parts to long, heavy or bulky goods.

And because it uses a modular designed bolt-free lock-in system requiring no special tools, it’s installed in minutes. Long spans versatility gives one system for a diversity of needs. Long span incorporates a wide range of beams and frames making it easy to customize to precise storage needs. Different bay lengths can be combined to store a wide range of items while purpose designed accessories extend versatility even further.

Multi-tier racking platforms maximizes all available headroom and is ideal for storing a wide variety of packaged goods for hand picking. It is the ideal solution for the utilizing of warehouse’s height and space. A Multi-tier racking floor offers a very cost-effective way of transforming unused headroom space into dynamic office, manufacturing or storage space, which allows a business to expand considerably within its existing premises.

Multi-tier racking is created using adjustable pallet racking. Additional storage floors can be incorporated into the rack with walkways to allow pedestrian access for order picking. This maximizes all available headroom and is ideal for storing a wide variety of packaged goods for hand picking.

- Economical use of cubic space

- Can accommodate a range of storage requirement

- Ideal for archive storage

- Manual order picking applications

- Can accommodate sophisticated automated picking system

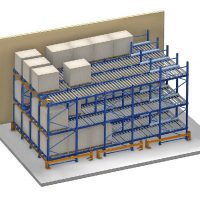

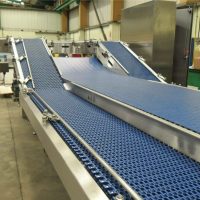

MEZZANINE FLOORS

Steel structural steel mezzanine floors an ideal solution for the utilizing of warehouse’s headroom height and space. They effectively capitalize on the cubic volume of a building freeing-up ground floor areas. The structures are manufactured to suit individual requirements and are delivered to site pre-fabricated enabling rapid on-site installation and Increases your floor area with minimal cost

Racks Supported Mezzanines Floors maximizes all available headroom and is ideal for storing a wide variety of packaged goods for hand picking. It is the ideal solution for the utilizing of warehouse’s height and space. A mezzanine floor offers a very cost-effective way of transforming unused headroom space into dynamic office, manufacturing or storage space, which allows a business to expand considerably within its existing premises.

Rack supported floors are an ideal solution to create an open floor space above a shelving or racking system that can be used for bulk storage or additional shelving.

A Floor over racking system is simply an area of shelving or racking with a lid on top that creates a floor accessed by a staircase.

A Rack Supported Mezzanine floor is the fastest way to add and use additional floor space within the shell of an existing building.

Raised storage areas provide the means to create separate zones within one centralized facility, so you can separate areas for bulky items, fragile items, warehousing and dispatch, fast moving and slow moving stock.

Each installation is tailored to the site and the load-bearing performance required – maximizing economy and safety.

Staircases, hand railings, catwalks, pallet gates, wooden floor panels, steel floor panels, goods chutes, offices & conveyors can also be included in the construction of these rack supported mezzanine systems.

Mezzanines can be erected in single, double or multi-tiers and to differing floor heights – which makes them suitable for commercial, retail, warehousing and virtually any type of production.

A further benefit is the ability to take down & relocate the structure at a later date.

Rack supported floors are a cost effective way of providing additional floor space when shelving is being used at ground level and negates the need for a structural mezzanine floor.